Parts That Fix Maytag Dryer MED7230HW1 Drum Not Spinning

The Drive Belt is a 93 1/2" belt which wraps around the dryer drum to allow tension and movement. If broken the dryer will not turn properly, or there may be loud noises. The part is rated as "medium" difficulty to install. Refer to your model number and user manual to ensure this part is correct for you. To complete this repair you will need a Phillips screwdriver, 1/4 inch nut driver, a putty knife, and a pair of needle nose pliers. Ensure you disconnect your power to the dryer before beginning this repair, which should take between 30 and 60 minutes maximum to complete.

Replacing your Whirlpool Dryer Multi Rib Belt

Customer Repair Stories

-

john from goldsboro, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

-

Larry from exeter, RI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

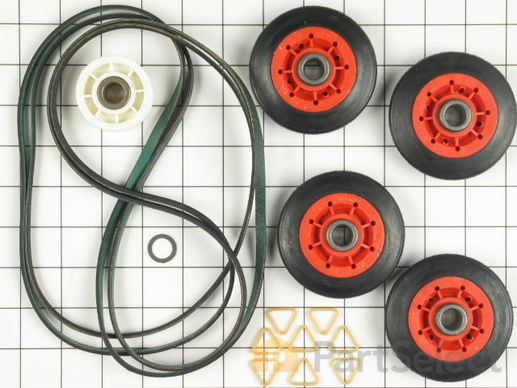

This Whirlpool Dryer Repair Kit is a convenient solution for fixing noise and drum movement problems in 27-inch dryers. Compatible with models from Whirlpool, Kenmore, Maytag, and more, the kit includes a drive belt, drum support rollers, an idler pulley, mounting clips, and a washer. It’s designed for straightforward installation using standard tools, and should only be installed after disconnecting power. Ideal for restoring smooth, quiet dryer performance, this kit combines essential components in one package to save time and effort during repairs. Installation requires disassembling the dryer to replace parts using standard tools. Ensure the dryer is unplugged before starting. This durable OEM kit provides reliable repairs for quieter, more efficient operation.

Replacing your Whirlpool Dryer Dryer Repair Kit

Customer Repair Stories

-

Eddie from PELZER, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

-

jason from HOLDEN, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

The idler pulley with bracket ensures proper tension on the dryer’s drive belt, allowing the drum to spin effectively. This assembly includes the pulley and arm, making it ideal for replacing a worn or damaged component. Designed for various Whirlpool, KitchenAid, Maytag, Jenn-Air, Amana, Inglis, and Magic Chef dryers, this genuine OEM part guarantees reliability and performance. If your dryer is noisy or the drum is not turning properly, this part may be the solution. Always disconnect power and wear gloves during installation.

Replacing your Whirlpool Dryer Idler Pulley with Bracket

Customer Repair Stories

-

Peter from HUEYTOWN, AL

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

-

Richard from SAUGERTIES, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

This Idler Pulley includes the tri-ring and gasket and everything included here is manufacturer-certified. This part maintains correct tension on the drive belt in order to spin the drum properly. If damaged or broken the dryer will not dry properly, will not tumble properly, or may not even start. Installation is rated as "Medium" difficulty. This part is located on the dryer drum, around the tension pulley. Refer to your user manual and model number for repair instructions and to ensure this part is right for you. For this repair project, the tools needed are a Phillips screwdriver, 1/4 inch nut driver, putty knife, small flat blade screw driver, and needle nose pliers.

Replacing your Whirlpool Dryer Idler Pulley

Customer Repair Stories

-

Robert from Princeton, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

-

GREGORY from Wilsonville, OR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

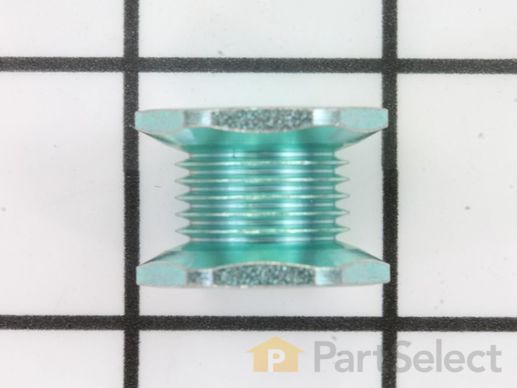

This part is the replacement motor pulley for your dryer. The motor pulley allows the dryer belt to run straight while the dryer is operating. If your motor pulley is damaged, your dryer may not tumble, and may not start altogether. A damaged motor pulley can also damage the dryer belt, and it may need to be replaced as well. Be sure to disconnect power from the dryer before you begin this repair. This motor pulley is a genuine OEM part sourced directly from the manufacturer.

Replacing your Kenmore Dryer Motor Pulley

Customer Repair Stories

-

Anthony from Lake Forest, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

-

Mark from PELHAM, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set

The blower shaft is 1-5/8 inches long, while the drive shaft is 1-1/4 inches long.

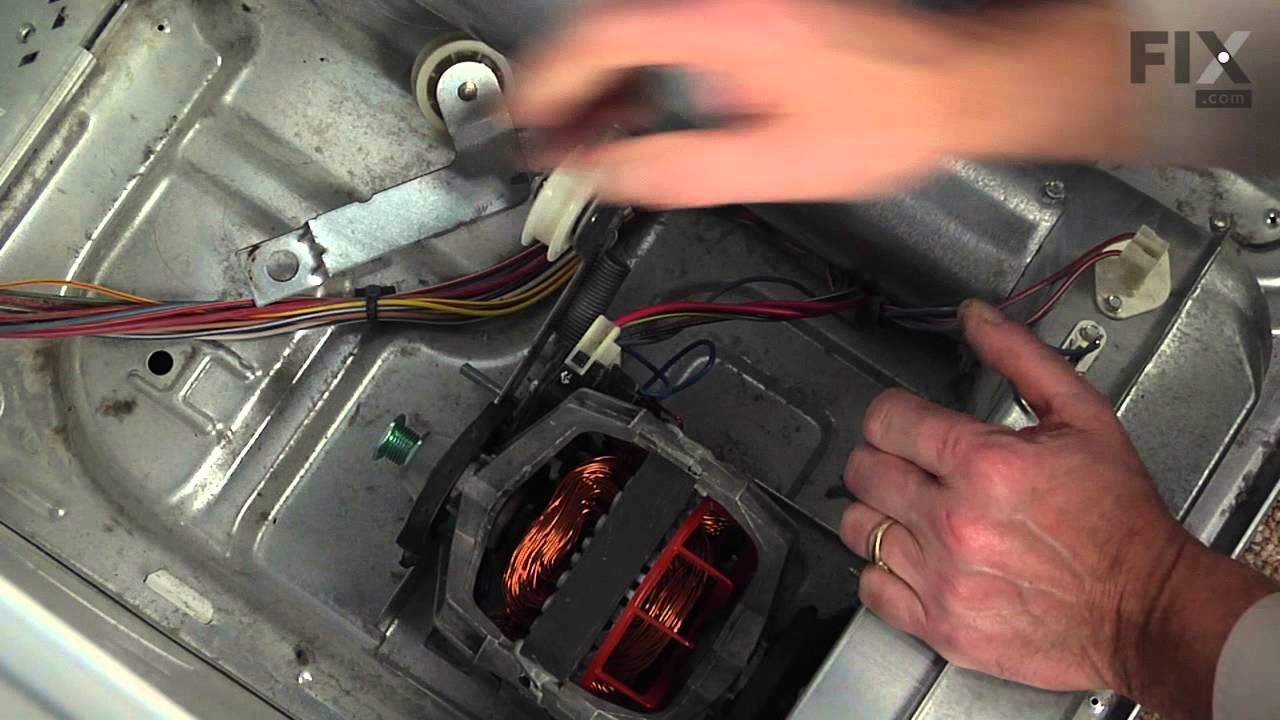

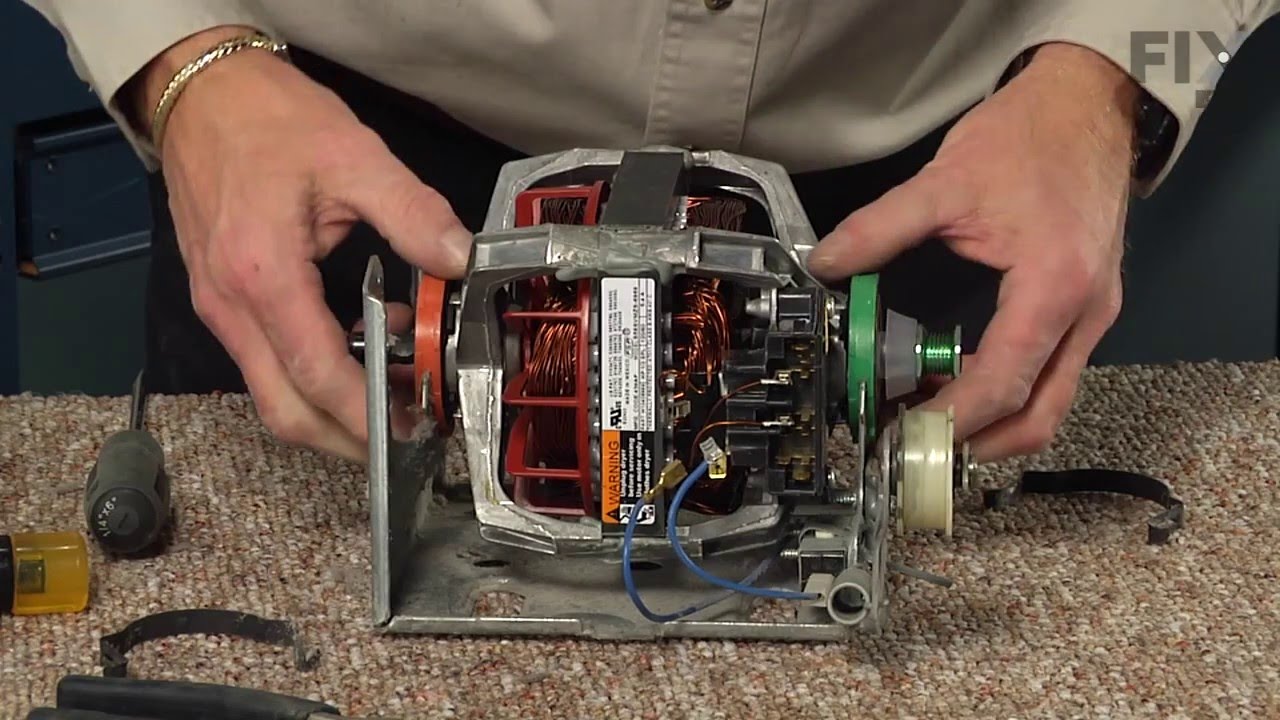

Replacing your Kenmore Dryer Drive Motor with Threaded Shaft - 120V 60Hz

Customer Repair Stories

I input the number into the search box and there was the exact motor I needed.

The correct part showed up in a timely manner and the pricing was very fair.

I disassembled the dryer, ... Read more removed the old motor and reinstalled the new motor within about 30 minutes.

Key point was to read the instructions first and then reconnect the wiring to the new motor. The new motor has the switch install in a different spot on the motor so be careful to follow the instructions but, the instructions were very clear and connections were very simple.

I also did some preventive maintenance while I was in the unit by cleaning out any remaining lint from the heater unit and surrounding areas, that took about 30 minutes. Reassembling was a snap and I turned on the gas, plugged it in and........SUCCESS! Total time of repair and cleaning was about an hour.

I had a load of laundry ready to go and put the new motor right to work. It has been non-stop drying and thanks to Part Select for getting everything right the first time. It has been a positive experience and I will tell others about the website if they have similar problems. Thanks again for a success story and dry clothing.

-

Keith L. from San Diego, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

I input the number into the search box and there was the exact motor I needed.

The price was fair and the delivery quick so I figured I would give yuo guys a shot and see how it goes.

The par ... Read more t showed up on time and as expected. It was well packed and most importantly - it was the CORRECT part.

I disassembled the dryer which involved removing the lint trap, pulling out the blower fan and removing the motor cover. The motor was held in with 2 metal screws and wiring harness.

I took the belt off of the tensioner and pulled out the old motor. The motor was mounted with 2 clips which snapped off with ease. Reassembly was a breeze since the motor fit perfectly- the entire transplant operation took all of about 35 minutes.

I crossed my fingers, turned on the gas, plugged it in and........SUCCESS!

Since the dryer was down for over a week the backlog of laundry was piled pretty high. This replacement motor would immediately be put to the test.

It has been 5 days of non-stop drying and no squeeks, no squeels and nothing but dry clothes!

Thanks to Part Select for getting everything right the first time. It made a potentially very bad experience turn out as good as I could have ever hoped.

-

Kelly from Aptos, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. This part is sold separately. Most dryers require two drum rollers. It is recommended to check and replace both drum support rollers at the same time to ensure proper drum rotation and because they often wear at the same rate. The drum support roller holds the drum in the proper position while it spins on the support wheels. If rollers are worn out, they will cause the dryer to be noisy.

Replacing your Whirlpool Dryer Dryer Drum Support Roller

Customer Repair Stories

-

Robert from GOODRICH, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

-

Jeff from Mesa, AZ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable), Wrench set