Parts That Fix General Electric Dryer GTD45EASJ0WS Noisy

This is a duct felt seal for a dryer. The duct felt seal allows the front-load dryer drum to glide smoothly on the front panel. Your dryer will not function properly if the drum felt seal is compromised. Disconnect power to the dryer before completing this repair. You will need to remove the front of the dryer to gain access to the felt seal. This felt seal may differ in appearance from your original but will function the same as your original. This is an OEM replacement part that is sourced directly from the authentic manufacturer.

Replacing your General Electric Dryer Felt Trap Duct

Customer Repair Stories

-

Tahir from ARLINGTON, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

-

gerard from goldsboro, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

This Drive Belt is 89.5" long and comes in black, featuring four ribs on the inside for a better grip. This is a long belt that wraps all the way around the dryer drum, around a tension pulley, and then around the drive motor pulley, allowing all the parts to work together, spinning the drum as the motor rotates. If the drum will not turn when the dryer is turned on the belt is likely broken. It is common for belts to stretch or become brittle over time, which is what leads to the breakage. If broken, it should be replaced; the drum simply cannot spin without this belt. Refer to your model number and user manual to check if this part is right for you. Ensure you use work gloves to protect your hands from sharp internal parts during this repair. Please note: When comparing the length of your old belt to the length of the belt as stated here, remember that a small amount of stretching and contortion may occur with belts over time for a range of different reasons. Unless your belt is drastically different in length, this belt is what you are looking for despite any small inaccuracies. You will need to remove power to your appliance, remove the main panel, and access the motor drive to slip your new belt back into place.

Replacing your General Electric Dryer Drive Belt

Customer Repair Stories

-

Richard from Ashton, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

This was a first attempt ever at fixing an appliance and it was no big deal.

-

Adrian from Middletown, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

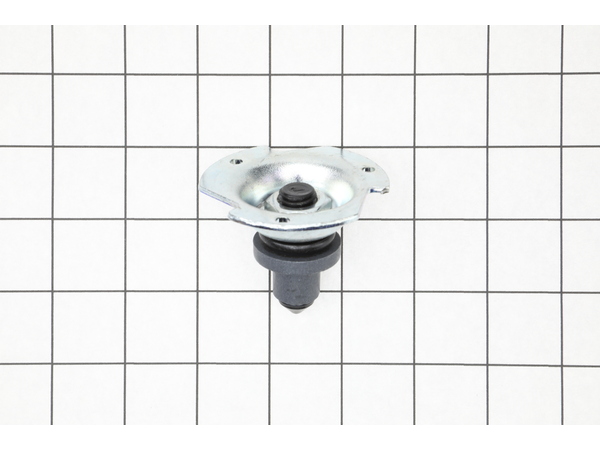

Keep your GE dryer running smoothly with this genuine OEM rear drum bearing sleeve, designed specifically for GE dryer models. This part supports the back of the dryer drum and helps reduce friction as the drum rotates, ensuring quiet and efficient operation. Common signs that this part may need replacement include unusual noises during operation, the drum stopping mid-cycle, or the drum failing to turn at all. Replacing the sleeve drum bearing is a straightforward repair that requires only a screwdriver. For safety, always disconnect the power before beginning installation. This part is sold individually and is a reliable solution for restoring your dryer’s performance and extending its lifespan.

Replacing your General Electric Dryer Dryer Drum Bearing Sleeve

Customer Repair Stories

-

Mary from Enterprise, AL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Our dryer was making a very annoying squeaking/rubbing noise while drying and it became worse as the outside temps dropped (it's winter)...colder air cooling the exhaust line, causing metal in dryer to contract more.

... Read more >I called an appliance repair service and they said, "Honestly, your money is going to be better spent to just buy a new dryer. The bearings on these are a pain to replace."

Yeah, right.

I've never taken apart a dryer, but it took me less than 45 minutes to complete this repair and our dryer is back to normal. Total cost was $18, including shipping. A $300 savings versus buying a new dryer.

There is another description of the process for this part so I won't repeat it all.

I did it a little differently than most, namely I did not remove the dryer drum. I simply pulled it out about six inches (make sure and slide belt back as you inch out the drum). But first, unplug the dryer, then remove the top, then the front.

A Philips screwdriver will quickly remove the top of the dryer (two screws on inside front, where door closes) and the front face (two screws at top of front, inside face). Lift the front up about an inch and it is free. I had to disconnect a couple wires, just make sure you mark before you disconnect them.

With that done, the drum will pull straight toward you (out). Make sure and support the weight of the drum as you slide it out. I found no need to remove the drum.

At the rear inside of our drum, there are three Torx screws that hold the bearing assembly on. I have a pretty long reach so I just removed two of the Torx screws, then reached around the back of the drum while removing the third screw, to keep the bearing assembly from falling onto the floor behind the back of the drum.

This plastic bearing is held to the bearing shaft by a little o-ring. Just pull the o-ring off, slide off the old bearing, slide the new bearing on and replace the o-ring (if yours is broken, any home store will have one that will work as a replacement in their faucet repair department).

Reattach the bearing housing to the drum with the Torx screws (get all three started before you tighten any of them), slide the drum back in - make sure you slide the belt as you move the drum back in and support the weight of the drum so you don't bash the bearing assembly into the back of the dryer.

You're doing this part blind, but in a few seconds, you can guide the bearing back into the hole in the back wall of the dryer. It just slides into the hole, nothing fancy.

Put the front of the dryer back on. Then replace the top (I had to remove the five screws on top of the dial panel to give it some flex so the top would pop back into place without stressing the dial panel), plug the dryer back in, and fire it up.

45 minutes after this part arrived at our home, our dryer problems were gone. Now that I've done one, I could probably do it in 20 minutes the next time (it's that simple/easy). And we didn't need a new dryer. Makes me think I should have the appliance guy who told me we needed a new dryer to direct all of these "pain in the fanny" bearing replacements to me because I could charge someone $50 total for the repair and make good money.

Hope all this babble helps someone else who doesn't need a new dryer.

-

Gary from Spring Hill, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

This drum glide bearing is an authentic OEM replacement part that is compatible with dryers. It is white in color and made of highly durable plastic. The bearing allows the drum to rotate smoothly and dry your clothes thoroughly and evenly. It keeps the drum stable and protects it from excessive friction damage. Over time, the bearing may wear down or break due to normal aging or wear from repeated use. If the bearing is no longer able to support the drum, you will likely notice unusually loud grinding or squeaking noises from the dryer. You may also notice increased drying times due to poor drum rotation. Inspect all the bearings on your dryer, as they tend to wear down at the same time. Each drum glide bearing is sold individually.

Replacing your General Electric Dryer Dryer Bearing Slide (2 Pack)

Customer Repair Stories

-

Maurice from MINERAL SPGS, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This OEM replacement dryer slide bearing is white in color, and approximately 3 inches long. The slide bearings are supportive linings for your dryer. If they have eroded, or are damaged, the drums will scrape against metal during the drying cycle which will produce a squealing, or scraping sound.

Replacing your General Electric Dryer Dryer Bearing Slide (2 Pack)

This authentic OEM rear bearing O-ring is designed for use with GE dryers. It helps secure the drum rear bearing onto the drum shaft, playing a key role in maintaining smooth and quiet dryer operation. A common sign that this part may need replacement is increased noise during the drying cycle. This O-ring is sold individually. To replace the O-ring, you’ll need a Phillips screwdriver, a square-head screwdriver, a small flat-blade screwdriver, and needle-nose pliers. Always consult your dryer’s manual or parts diagram to ensure proper installation and compatibility.

Replacing your General Electric Dryer Dryer Retainer O-Ring

This is 39 inches long.

Customer Repair Stories

-

MARTIN from MOUNTAIN VIEW, WY

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

This GE drum support shaft and bracket assembly provides solid support for the drum at the back wall of your dryer. The design ensures smooth rotation of the drum whilst it performs its drying function. It's crucial to disconnect the dryer from its power source before beginning the installation process. Additionally, wearing work gloves during assembly can offer protection for your hands. This GE drum support shaft and bracket assembly ensures your dryer delivers optimal performance at all times. Purchase today and experience the quality and longevity that exemplifies GE appliances.

Replacing your General Electric Dryer Dryer Shaft & Bracket Assembly

Customer Repair Stories

-

Armando from WESTMINSTER, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Introducing the GE Idler Pulley Wheel, a crucial component for your dryer. This item is crafted from highly durable plastic, ensuring long lasting durability. The idler pulley wheel is responsible for maintaining the correct tension on the drive belt so that the drum can spin properly, ensuring your dryer operates smoothly. Safeguard your hands by wearing work gloves during installation and always remember to disconnect the power before starting. Trust this GE product to keep your dryer performing at peak efficiency!

There is a slot in it for a ground strap.

This part, along with the idler pulley wheel, helps the belt to rotate the drum.

Introducing the top-quality GE Dryer Top Bearing Assembly. This essential piece reinforces the front of your dryer drum, significantly reducing friction as it rotates. The assembly incorporates the bearing, bearing slides, drum light, and drum light socket. This brilliant design enables a smooth and efficient operation of your appliance. Prior to the installation of this superior GE part, remember to unplug your dryer and protect your hands by wearing work gloves. Inject efficiency into your laundry routine with this top bearing assembly from GE.