9114282790 Kenmore Cooktop - Overview

Sections of the 9114282790

[Viewing 2 of 2]Keep searches simple, eg. "belt" or "pump".

Burner Bowl

PartSelect #: PS8754845

Manufacturer #: WB31K10265

This 6" chrome drip bowl is sold individually.

$13.95

In Stock

Chrome Burner Bowl (8 Inch)

PartSelect #: PS8754846

Manufacturer #: WB31K10266

This burner drip bowl, also referred to as a drip pan or burner pan, is a genuine OEM replacement part that is designed to fit ranges. The bowl is located beneath the burner where it catches food part...

$14.95

In Stock

Range Surface Burner Terminal Block Kit

PartSelect #: PS242972

Manufacturer #: WB2X8228

Also known as receptacle.

$35.95

In Stock

Range Terminal Block

PartSelect #: PS232646

Manufacturer #: WB17X5113

This kit includes one ceramic block with 6" wire leads, 2 wire nuts and 2 heat shrink with mounting bracket.

$35.95

In Stock

Porcelain Drip Bowl - 6 Inch

PartSelect #: PS244375

Manufacturer #: WB31M20

This is a replacement drip bowl for your range. It is black in color and is approximately 6 inches in diameter. The bowl is made of porcelain and is sold individually. The drip bowl rests under the bu...

$10.95

In Stock

Porcelain Drip Bowl - 8 Inch

PartSelect #: PS244373

Manufacturer #: WB31M19

This 8" drip bowl is intended for use with loop style surface mount burner element units.

$11.95

In Stock

Switch Seal

PartSelect #: PS243590

Manufacturer #: WB2X9504

This part goes between the infinite switch (under the cooktop) and the knob.

No Longer Available

Infinite Burner Switch

PartSelect #: PS236434

Manufacturer #: WB23X10009

Sold Individually. Order quantity required.

No Longer Available

Grille Grate

PartSelect #: PS244782

Manufacturer #: WB32X5058

Sold individually.

No Longer Available

Questions And Answers for 9114282790

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Symptoms of the 9114282790

[Viewing 2 of 2]Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

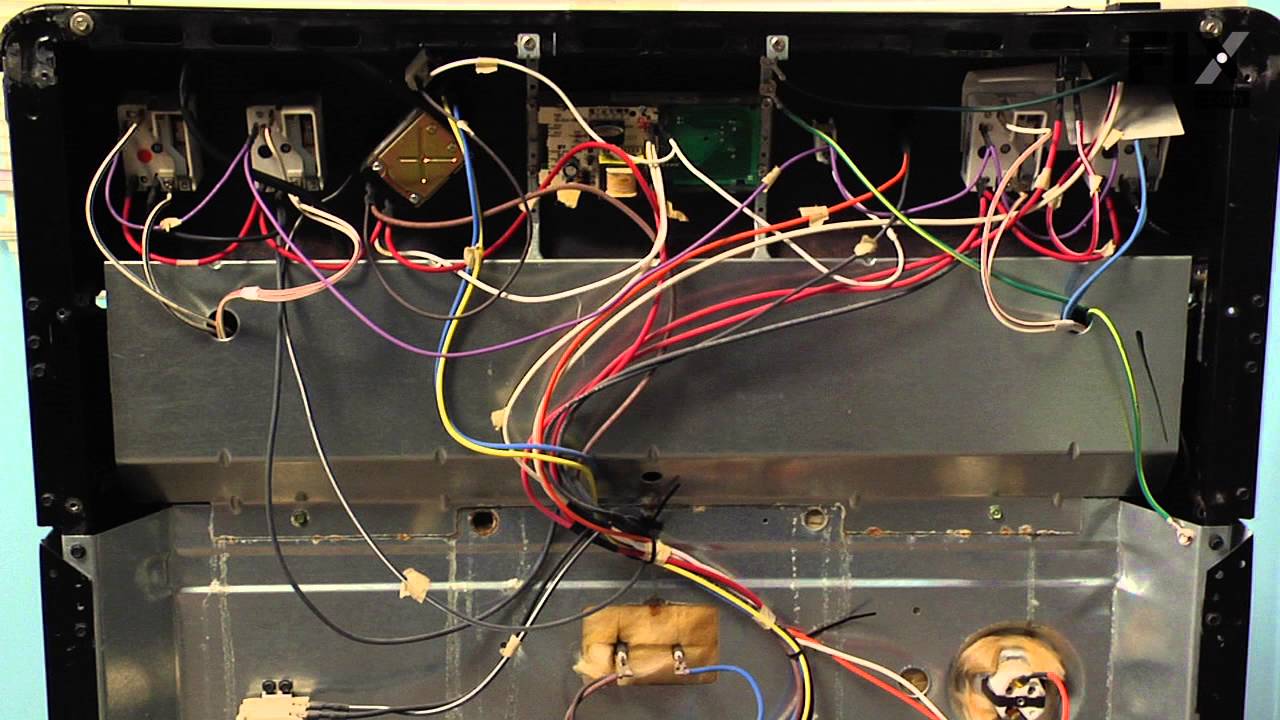

The Bake-o-lite (Hard Plastic) block that holds the burners female connection in place had chipped away over time and wouldn't allow the male part of the burner to connect up correctly.

After unplugging the range I took the rear sheet metal panel at the top off with a nut driver to expose the wiring connections. The next step was to remove the single screw holding the old part in place. (under the drip pan) Once free I snipped the old part from the wires and then taped the new female ends to the old wires with black elec

... Read more

trical tape. From rear I carfully pulled the old wires through the back until I could reach the new wiring connections. Unplugged old, plugged in new and replaced the rear metal cover. Then I put the screw that holds the new block bracket in place, replaced drip pan, and burner. The final step was to plug the range back in and check to see if the burner worked. It did and I was done. Approx. 5 minutes

Read less

Parts Used:

-

Robert from Mt. Vernon, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

113 of 115 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I had 2 of the terminals where the burner coil plugs into completely fry

First thing to do is to KILL THE POWER. The last thing you want is for two leads feeding power to a range coil burner "hot" when you are working on them. After power is off, I removed the coils and set them aside. The terminals had "fried" apparently from to much cooking with hot oils and having the "over splash" working its way down t

... Read more

o where the coils plug into the terminals and over time the oil getting in the terminals causes shorting / frying of the leads / contacts.

Anyway, after removing the heat coils I removed the drip pans and cleaned up the area underneath before working on terminals. I like a clean area when I work. I then unscrewed the "brackets" that house the terminals with a Phillips screwdriver and pulled out the assembly.

To completely remove the assembly I cut with a straight razor the existing heat shrink around the wire nuts (These two had been replaced once before. On first go around, I just cut the terminal assembly off and stripped the wire to attach the new terminals). Then I removed the wire nuts and the old assembly. After that I trimmed the wire to the correct length on the new terminal assembly and checked that the wire from the stove was in good shape. Upon confirming I had a good lead, I connected the new terminal leads to the stove leads and put the heat shrink over the connections. I used a lighter to "shrink" the heat shrink to the new connection (not having a proper heat shrink gun, which most of us don't have, the lighter works well as long as you are careful and do not let the lighter heat up to much. Let the lighter cool (esp. if a plastic disposable type or it will melt and ruin the lighter or burn your fingers).

After that I cleaned the area where the terminal block bracket connects to the stove (it gets a bit gunked up over time) before screwing in the new bracket / assembly in place with my screwdriver.

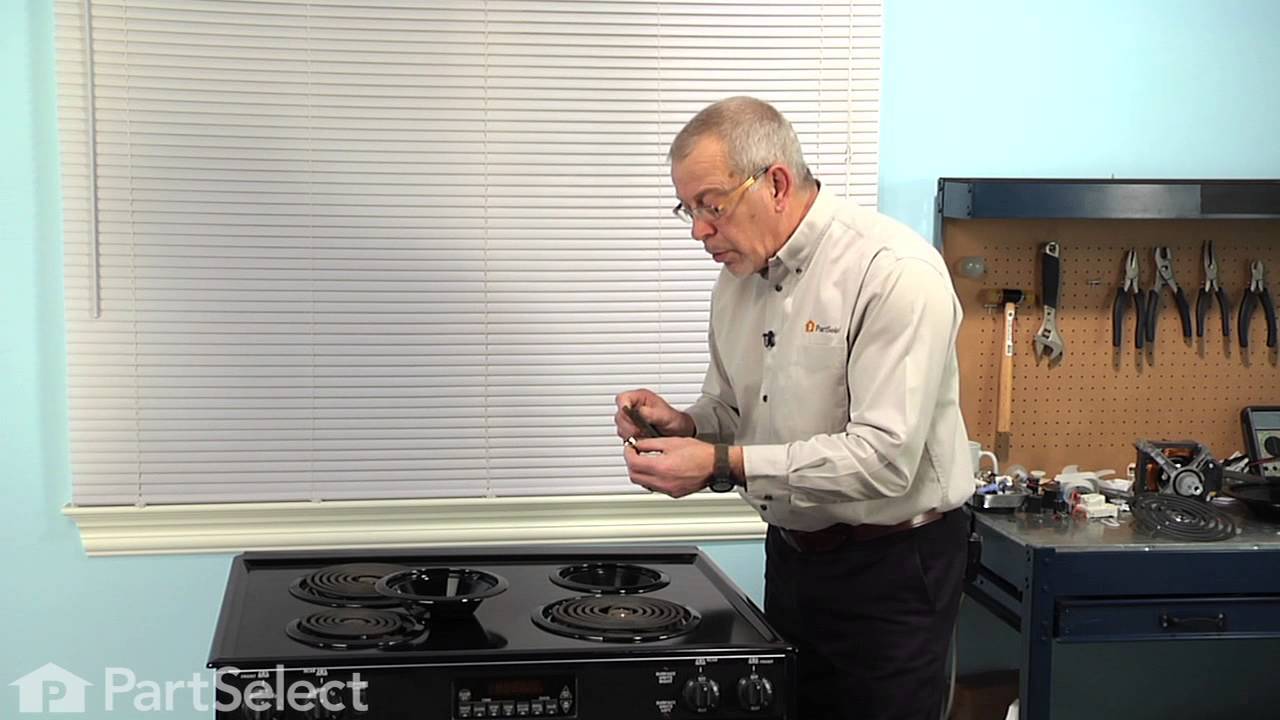

I gave the drip pans a good cleaning, adjusted the new terminal brackets so they were even / centered, cleaned once more the area under the drip pan and replaced the drip pans. The types of pans I have are one piece with a hole for the heat coil leads to go through.

Before placing the coils back in the terminals I took a strip of medium grade, 220 grit, sand paper (you could use steal wool or small wire brush) and cleaned the terminal leads (the steal end that plugs into the terminal only, careful not to damage the burner). This was needed as the leads had accumulated some residue from the same dynamics that caused the burning / melting of the terminal leads and terminal block. Once the leads were clean I fitted them into the place in the new terminal blocks and drip pan grooves.

Finally I turned back on the breaker to the stove and cranked on the burners to test out the connection and that everything was working A-OK.

Job done:-)

Anyway, after removing the heat coils I removed the drip pans and cleaned up the area underneath before working on terminals. I like a clean area when I work. I then unscrewed the "brackets" that house the terminals with a Phillips screwdriver and pulled out the assembly.

To completely remove the assembly I cut with a straight razor the existing heat shrink around the wire nuts (These two had been replaced once before. On first go around, I just cut the terminal assembly off and stripped the wire to attach the new terminals). Then I removed the wire nuts and the old assembly. After that I trimmed the wire to the correct length on the new terminal assembly and checked that the wire from the stove was in good shape. Upon confirming I had a good lead, I connected the new terminal leads to the stove leads and put the heat shrink over the connections. I used a lighter to "shrink" the heat shrink to the new connection (not having a proper heat shrink gun, which most of us don't have, the lighter works well as long as you are careful and do not let the lighter heat up to much. Let the lighter cool (esp. if a plastic disposable type or it will melt and ruin the lighter or burn your fingers).

After that I cleaned the area where the terminal block bracket connects to the stove (it gets a bit gunked up over time) before screwing in the new bracket / assembly in place with my screwdriver.

I gave the drip pans a good cleaning, adjusted the new terminal brackets so they were even / centered, cleaned once more the area under the drip pan and replaced the drip pans. The types of pans I have are one piece with a hole for the heat coil leads to go through.

Before placing the coils back in the terminals I took a strip of medium grade, 220 grit, sand paper (you could use steal wool or small wire brush) and cleaned the terminal leads (the steal end that plugs into the terminal only, careful not to damage the burner). This was needed as the leads had accumulated some residue from the same dynamics that caused the burning / melting of the terminal leads and terminal block. Once the leads were clean I fitted them into the place in the new terminal blocks and drip pan grooves.

Finally I turned back on the breaker to the stove and cranked on the burners to test out the connection and that everything was working A-OK.

Job done:-)

Read less

Parts Used:

-

PATRICK from WASHINGTON, DC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Terminal block melted

First I unplugged the stove, then lifted the stovetop, then took off the top panel on the back and disconnected the two wires. Then unscrewed the terminal block and put the new one in its place. Lowered the top inserted the eye and replaced the back panel. Works great!

This is the second time in a few months that I replaced th ... Read more is terminal block, so I made sure the contacts were clean and smooth. I also made sure the contacts were completely inserted in the block.

This is the second time in a few months that I replaced th ... Read more is terminal block, so I made sure the contacts were clean and smooth. I also made sure the contacts were completely inserted in the block.

Read less

Parts Used:

-

J. Michael from Westfield, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!